Good Performance Metal Honeycomb Substrate Metallic Substrate Catalytic Converter

Beihai Xiaoming International Import and Export Trading Co., Ltd.- Type:Catalytic Converter

- Body Material:Steel

- Discharge Standard:Euro V

- Certification:ISO9001, TS16949

- Noise Source:The Noise of Engine

- The Noise of Engine:Mechanical Noise

Base Info

- Model NO.:MHS

- Automobile Chassis Noise:The Brake Noise

- Component:Catalytic Converter

- Main Market:North America

- Material:SS304, SS316

- Application:as Catalyst Used in Automobile,Motorcycle

- Cell:100-600cpsi

- Thickness(mm):0.04-0.1

- Width(mm):10-250

- Max Working Temperature:1100°c

- Max Service Temperature:1250°c

- Transport Package:Wooden Box and Pallet,Packed as Customers′ Need

- Specification:all size

- Trademark:DXY

- Origin:China

- HS Code:84213990

- Production Capacity:100, 000pieces,Month

Description

Basic Info.

Model NO. MHS Automobile Chassis Noise The Brake Noise Component Catalytic Converter Main Market North America Material SS304, SS316 Application as Catalyst Used in Automobile/Motorcycle Cell 100-600cpsi Thickness(mm) 0.04-0.1 Width(mm) 10-250 Max Working Temperature 1100°c Max Service Temperature 1250°c Transport Package Wooden Box and Pallet/Packed as Customers′ Need Specification all size Trademark DXY Origin China HS Code 84213990 Production Capacity 100, 000pieces/MonthProduct Description

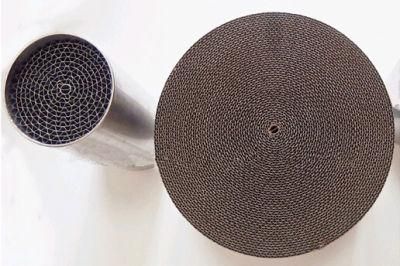

Metallic Honeycomb Substrate Description:Metallic substrate is with the advantages of fast burning, small volume, high mechanical strength, prominent heat-resistance, etc. It is widely used in exhaust gas purification, especially for motorbike. High strength complex substrate plus big surface area and active element of noble metal could lower down pollutant value of motorcycle exhaust efficiently, such as CO, HC, NOX etc...And such kind of catalyst is of excellent catalytic activity and durability that could reach Euro emission standard 3, meet requirement and have approval of EPA and E-MARK.

Advantages:

*Catalyst type: Complex catalyst of noble metal (PT, Pd, Rh) plus rare earth complex catalyst.

*Catalytic substrate: Metal substrate and honeycomb ceramic substrate.

*Fantastic coating fastness and stably and long-term catalyst ability.

*Advanced technic of substrates making and canning, ensuring depandable resistance heat shocks and stability of equipment.

*Various kinds of specifications and types, customized products as per clients specific requirement and technology data.

Remark: We can produce Metallic Substrate coated with noble metals of PT, Pd and

Rh and without precious metals as well.

We mainly produce auto catalyst used for vehicles, motorcycles, ATV, universal engine, garden machinery and agricultural cultivating machinery according to its features:

*Low light-off temperature

*Long-term durability performance

*Key material imported from Japan and Germany

*contain noble metal: PT/ Pd/ Rh

*Meet the Standards Euro II ~ Euro V emission standard, EPA, CARB approved

| Shape | Shell size(mm) | Core size(mm) | Cell density (CPSI) |

| Rotundity | Ø 30x22 | Ø 28X20 | 100/200/300/400 |

| Rotundity | Ø 35x20 | Ø 33X20 | 100/200/300/400 |

| Rotundity | Ø 35x30 | Ø 33x30 | 100/200/300/400 |

| Rotundity | Ø 35x40 | Ø 33x40 | 100/200/300/400 |

| Rotundity | Ø 35x50 | Ø 33x50 | 100/200/300/400 |

| Rotundity | Ø 35x60 | Ø 33x60 | 100/200/300/400 |

| Rotundity | Ø35 x 70/100/130 | Ø33 x 60/90/120 | 100/200/300/400 |

| Rotundity | Ø42 x 70/100/130 | Ø40 x 60/90/120 | 100/200/300/400 |

| Rotundity | Ø45 x 70/100/130 | Ø43 x 60/90/120 | 100/200/300/400 |

| Rotundity | Ø63.5 x 85/100/130 | Ø60.5 x 74.5/90/120 | 200/300/400 |

| Rotundity | Ø73 x 70/100/130 L | Ø70 x 60/90/120 | 200/300/400 |

| Rotundity | Ø93 x 70/100/130 | Ø90 x 60/90/120 | 200/300/400 |

| Rotundity | Ø100.3 x 100/130 | Ø98.3 x 90/120 | 600 |

| Rotundity | Ø144 x 150/152.4 | Ø142 x 140/142.4 | 200/300/400 |

| Rotundity | Ø190 x 200 | Ø188 x 190 | 200/300/400 |

| Rotundity | Ø420 x 100/130 | Ø416 x 90/120 | 300/400 |

| Race track | 123x63x85 | 120x60x75 | 200/300 |

| Race track | 123x63x100 | 120x60x90 | 200/300 |

| Race track | 78.5x52x104 | 76.5x50x90 | 200/300 |