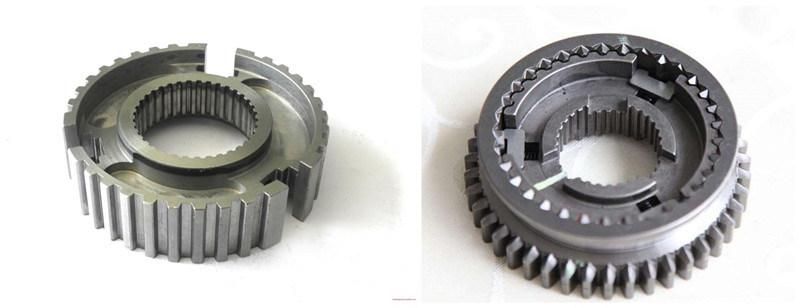

Factory Customized High Precision Sintered Synchronizer

Shijiazhuang Jingshi New Material Science and Technology Co., Ltd.- After-sales Service:1year

- Warranty:1year

- Camshaft Layout:Mid Mounted

- Valve Layout:Top Mounted

- Component:Valve Driving Assembly

- Working Rotate Speed:3500r,Min

Base Info

- Intensity:394.2MPa

- High-Frequency Quenching:Hra60

- Integral Quenching:HRC40

- Density:6.8g,cm3

- Precision:Grade 8

- Transport Package:PE Bag, Bubble Bag, Carton, Pallet

- Trademark:HLXCL

- Origin:China

- HS Code:8483409000

- Production Capacity:500000pieces,Year

Description

Basic Info.

Intensity 394.2MPa High-Frequency Quenching Hra60 Integral Quenching HRC40 Density 6.8g/cm3 Precision Grade 8 Transport Package PE Bag, Bubble Bag, Carton, Pallet Trademark HLXCL Origin China HS Code 8483409000 Production Capacity 500000pieces/YearProduct Description

Factory customized high precision sintered synchronizer and ring gearThe appearance of a gear tooth caused by a shift.The tooth hub of the powder metallurgy car is one of the important parts in the synchronizer

3500r/min drive torque is 145n. M: mechanical performance requirements: strength 394.2mpa hardness: (high-frequency quenching) > HRA60, (overall quenching HRC40: technical requirements: density 6.8g/cm3

Powder mixing - Forming - Sintering - Oil impregnation - Sizing -Ultrasonic cleaning - Steam oxidation - Oil impregnation - Final inspection - Packing

Company Profile

JINGSHI established in 2007

Manufacturer & Exporter

Exacting in producing powder metallurgy gears and parts

Passed ISO/TS16949 Quality Certificate

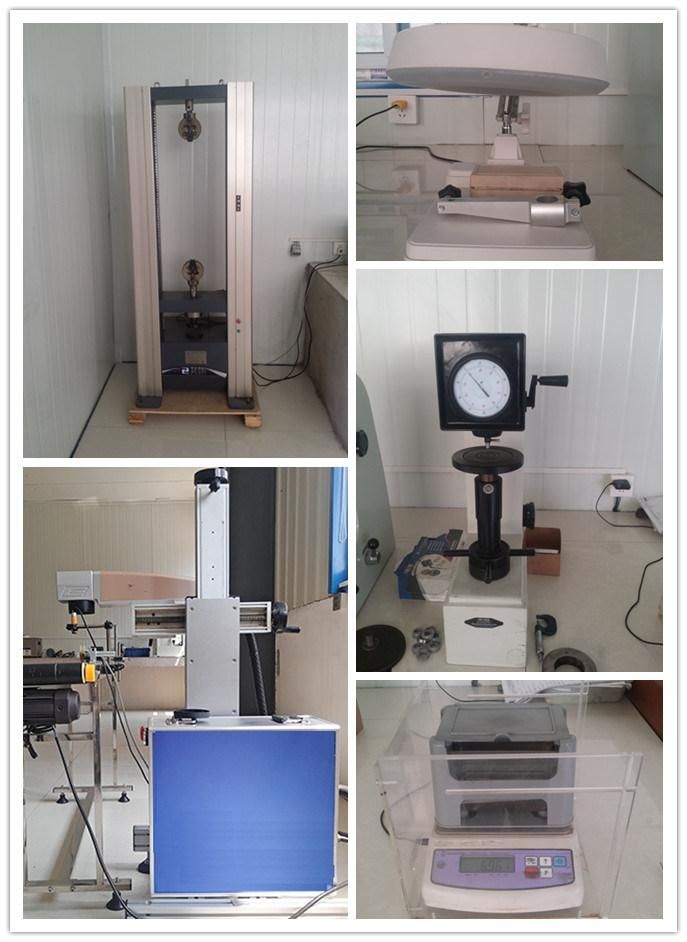

Advanced Equipment

Numbers senior R & D engineers and Skilled operators

Precise Examination Instruments.

Strict Quality Control

With the "More diversity, More superior, More professional " business purposes, we are committed to establish long-term friendship and win-win relationship with domestic and international customers to create a bright future .

Just to send your 2D or 3D drawing to start our cooperation!