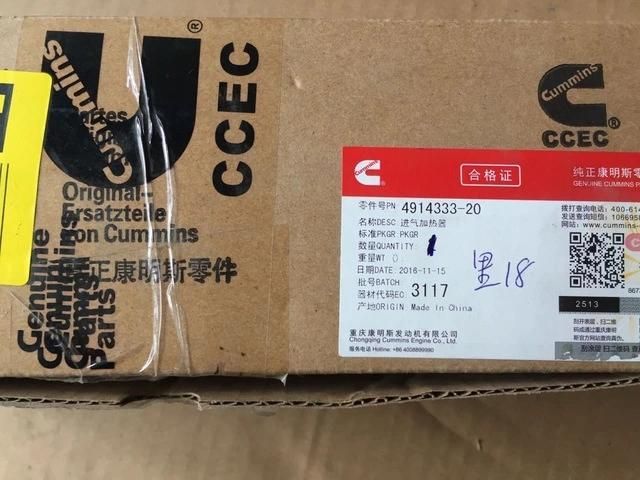

Nt855-C280 Engine Intake Heater 4914333 for Cummins

Xiamen HiuGong Machinery Co., Ltd.- After-sales Service:Free Services and Repairs

- Warranty:Free Services and Repairs

- Classification:Supersonic Inlet

- Material:Steel

- Placement:Pump Barry

- Certification:ISO9001, CE

Base Info

- Model NO.:HGBP4019

- Type:Inner Tube

- Adjustable Air Inlet:Two Dimensional Adjustable

- Supersonic Inlet:External Pressure

- Shock Wave Number:2 Wave

- Main Market:East Asia

- Profile:Polyhedral

- Transport Package:Carton Box

- Specification:0.5-3.5 cum

- Trademark:OEM

- Origin:China

- HS Code:7326909000

- Production Capacity:50000

Description

Basic Info.

Model NO. HGBP4019 Type Inner Tube Adjustable Air Inlet Two Dimensional Adjustable Supersonic Inlet External Pressure Shock Wave Number 2 Wave Main Market East Asia Profile Polyhedral Transport Package Carton Box Specification 0.5-3.5 cum Trademark OEM Origin China HS Code 7326909000 Production Capacity 50000Product Description

| HEADLINE | Cummins NT855-C280 Engine intake heater 4914333 |

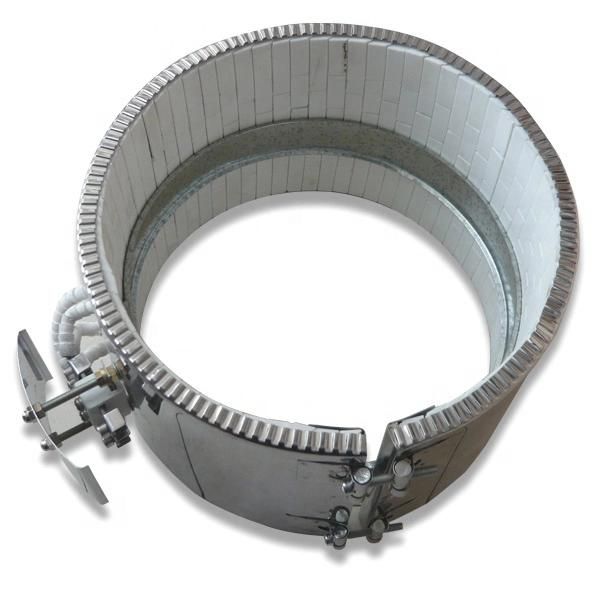

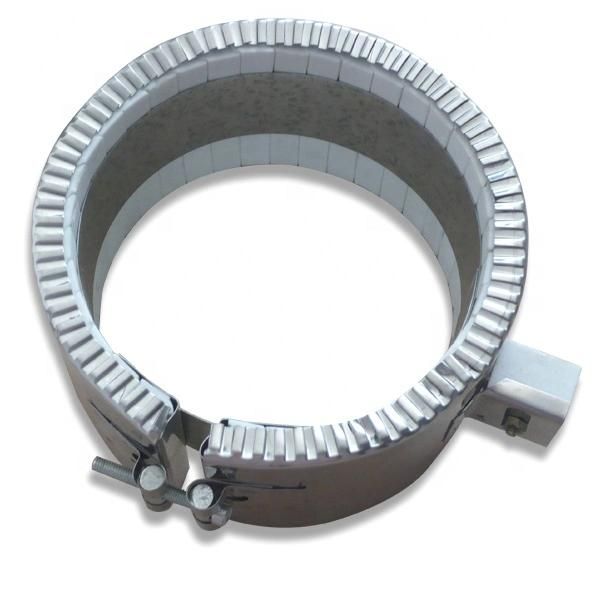

| PART NAME | Intake heater |

| PART NUMBER | HGBP4019 |

| MATERIAL | Steel, SUS. |

| FEATURES | Ceramic band heaters are medium-to-high temperature heaters that have 500ºC as a maximum working temperature. They provide long life and use less wattage (because of insulation) in plastics extrusion and injection molding applications. Ceramic band heaters are available with different terminal styles, are fully flexible, and can accommodate holes and cut-outs. Songtai Factory engineering is available to assist with the design and development of special heaters for particular requirements. » Top quality mica of various thicknesses » Maximum sheath temperature: 400ºC » External metallic sheath includes a special alloy » Broad range of construction designs, clamping mechanisms, and electrical terminal types |

| PRODUCT APPLICATION | 1, Plastic processing machinery 2, Injection and blow moulding 3, Hot runner bushings 4.Plastic injection moulding machine 5.Hollow shaping machine/Blow-molding machine 6.Extrusion machine/Co-extrusion line 7.Raw material processing equipment 8.Pelletizing equipment 9.Granular machine 10.All types of plastics processing machines |

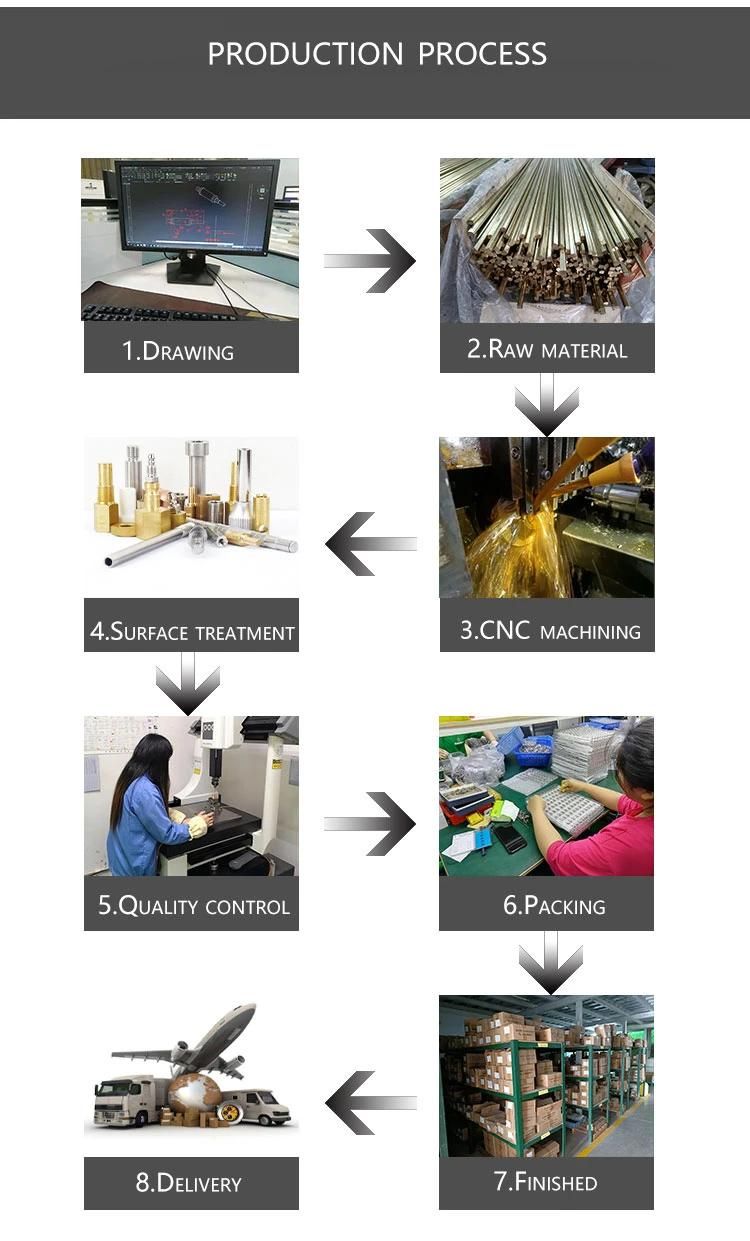

| MANUFACTURING PROCESS | Moulding, Injection, Cutting, surface treatment. |

| MOQ | 100 pcs. |

| PACKAGE | 1), With plastic bag,with pearl-cotton package. 2), To be packed in cartons. 3), Use glues tape to seal cartons. 4), Wooden pallet 5), According to customers' requirement. |

| PAYMENT TERM | T/T, Western Union. |

| DELIEVERY TIME | Within 15 workdays according to your order. |

| TRANSPORTATION | DHL/FEDEX/UPS/TNT/ARAMEX, AIR & SEA |

Sheet metal products have the characteristics of light weight, high strength, conductive, low cost, good performance in large scale production, and have a wide range of uses. Sheet metal processing has been widely used in the fields of electronics, communication, automobile industry, medical equipment, etc., such as in computer cases, mobile phones, MP3, sheet metal is an essential part. It is also used in the manufacturing of medical devices, car and truck bodies, aircraft fuselages and wings, medical tables, building roofs and many other applications.