Aluminum Bar and Plate Oil Cooler for Komatsu PC200-6

Wuxi Jiushengyuan Science & Technology Co., Ltd.- Component:Oil Cooler

- Body Material:Aluminium

- Cold Style:Oil Cooler

- Certification:ISO9001, CE

- Structure:Sealed Type

- Cooling Fluid Type:Oil Cooler

Base Info

- Model NO.:PLS00050- PC200-6

- Radiator Type:Plate and Bar

- Radiator Core Type:Tube-fin

- Water Temperature Sensor Type:No

- Cooling Fluid Brand:as You Choose

- Name:Alunimum Bar and Plate Radiator for Komatsu

- Color:Black or Silver

- Cooler Type:Oil Cooler

- Technique Method:Brazed,Welding

- Test:100% Passed

- Service:ODM OEM

- Company Type:Manufacturer

- Keyword:Heat Exchanger, Oil Cooler, Cooler

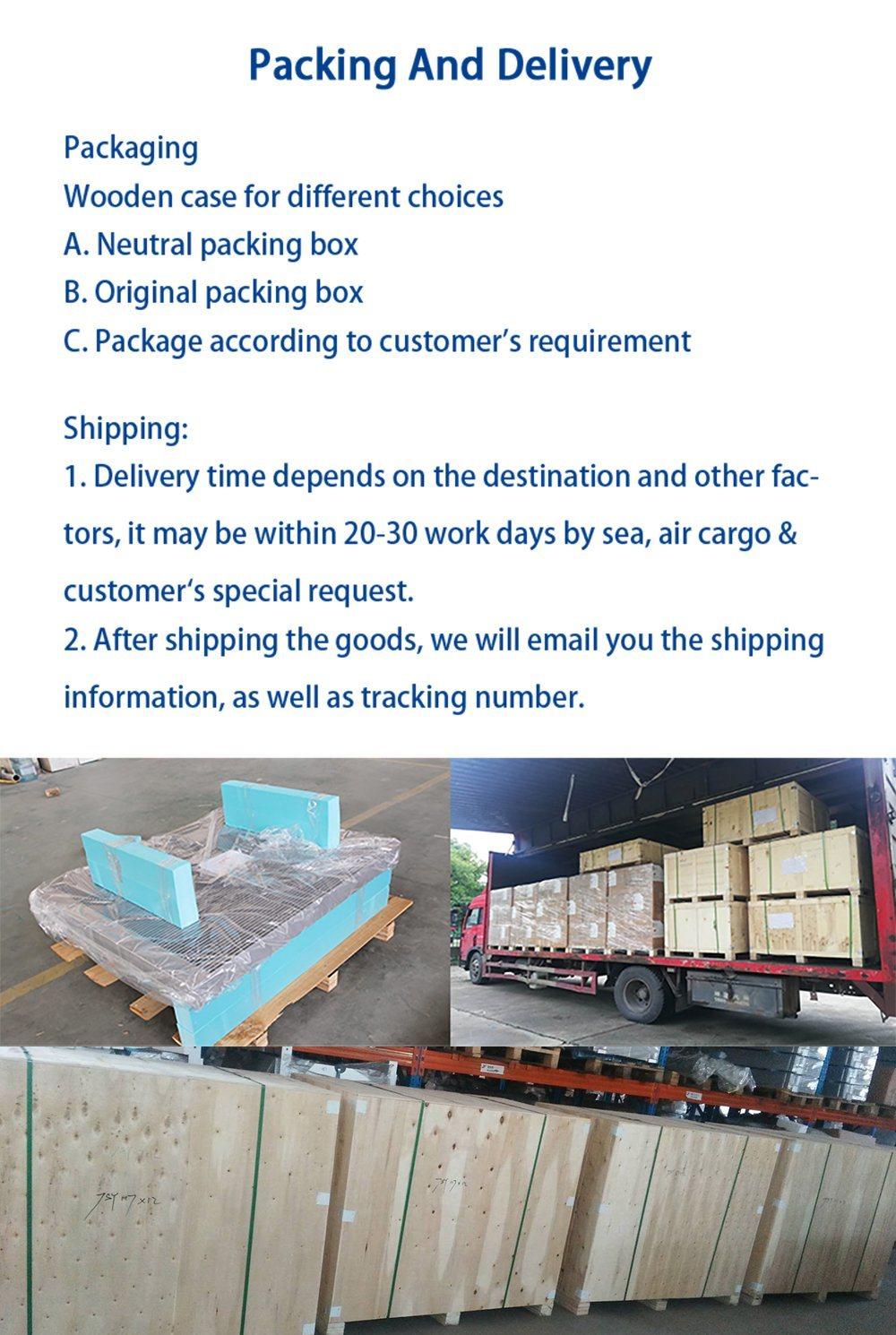

- Transport Package:Wooden Box or Carton

- Specification:CE, ISO9001

- Trademark:JS Brand

- Origin:Jiangsu, Wuxi

- HS Code:8419500090

- Production Capacity:3000 Tons,Year

Description

Q1: Could you custom oil cooler/heat exchanger? Q5. What is the lead time? A: We can manufacture pfate-fin heat exchanger/oil cooler A' For oil cooler/heat exchanger, normally 20-30 working Q2:1 want to buy your products, how can I pay? Q6 Can we buy 1 pc of each item for quality lesting? A: You can pay via T/T A: Yes. we understand quality test is important and we are Q3: How can you guarantee the quality? Q7: Can you pul our logo on the plate-fin heat exchanger/oil A: One year's warranty against B/L date. If You meet wilh A: Yes, please provide the finished design of your Q4: If we don't find what we want on your website, what A: You can email us the descriptions and pictures of the

Main Market:District Export Percentage District Export Percentage Europe 20% South America 15% American 17% Southeast Asia 13% Canada 13% Russia 18%

01 VACUUM BRAZING

01 VACUUM BRAZING

1.We have professonal qualification certificate of brazing operators.Different products adopt different brazing processes and set corresponding load thermocouples.

2.The surface of the brazing seam is complete,continuous,uniform and smooth.No solder accumulation,overflow, splashing exist.No unmelted or cracks on the surface.02 ARGON ARC WELDING

1.We have professional qualification certificate for argon welding operators and Welder Skill Matrix.

2.The crater should be filled up and slightly higher than the base metal.The arc crater must not have cracks and shrinkage holes.Backing plate welding is usedfor arc startng and closing.

3.Special processes such as double-sided welding,multi-layer welding,and penetration welding eliminate welding defects and ensure welding quality.

4.The weld surface is straight,beautiful,with uniform scales and uniform height.No surface pores,cracks,obvious bens and serious welds.

5.Develop different standard welding operation onstructions for different products(SOP).

03 CLEANING

03 CLEANING

Before brazing,in addition to ultrasonic cleaning(removing oil anddust),alkali cleaning and acid cleaning (Remove surface oxide film)are also carried out.04 ASSEMBLY

1.Use a torque wrench and use the same force to make the force on all sides even.

2.Hydraulic shaping to ensure the flatness and verticality of the product core.

3.Equipped with welding tooling and inspection tools.

High effiency and high fiow are the characteristics we have worked hard to obtain.Highly polished end tank ensure the best heat reflection and appearance.

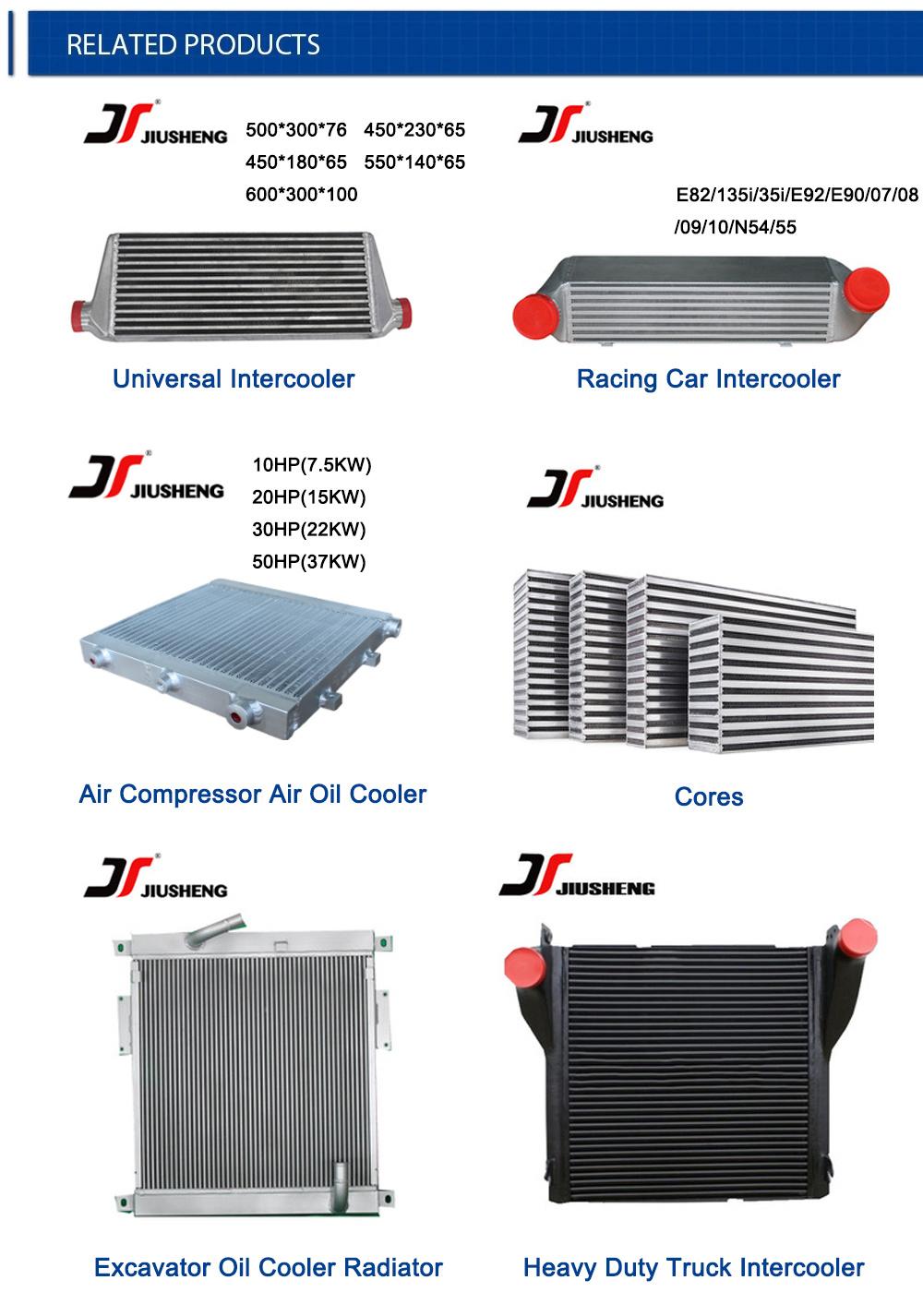

We have following intercoolers.We are also welcome your own design.pls feel free to contact us if you have any other questions.

Our company is a professional manufacturer specialized in producing all kinds of aluminum heat exchangers. Our factory is located on the bank of the Taihu Lake & in the west suburb of Wuxi. Our aluminum plate-fin heat exchangers feature high heating efficiency, small size, light weight and strong applicability. Our products are widely applied in engineering machinery, air compressors, vehicle separation, construction machinery separation, hydraulic transmission oil radiators, wind and electricity, electrical locomotive separation and boat separation as well as many other fields. Our products sell well in France, Germany, Italy, the USA, Canada, Japan, Korea and New Zealand.

/intercooler according to your drawings or samples.

days lead time is calculated from the day we receive your

deposit. Exact time is determined by factory schedule.

glad to send 1pc for quality testing.

cooler /intercooler?

quality problem, we promise to replace goods.

logo, we will make it into stickers.

should we do?

products you need. We will check whether we can make it.