Stainless Steel Vacuum Cutout Exhaust Valve with Normally Open Style

Qingdao Cartier Industry and Trading Co., Ltd.- Type:Exhaust Pipe

- Body Material:Steel

- Discharge Standard:Euro III

- Certification:ISO9001

- Noise Source:The Noise of Engine

- The Noise of Engine:Aerodynamic Noise

Base Info

- Model NO.:GW-C001-NPV-51

- Automobile Chassis Noise:Aerodynamic Noise

- Component:Exhaust Valve

- Main Market:South America

- Name:Exhaust Valve

- Color:Silver

- Material:Stainless Steel 304

- Surface:Mirror Polish

- Packing:Carton Packing

- Certificate:ISO9001:2000

- Transport Package:Carton Packing

- Specification:stainless 304

- Trademark:GRWA

- Origin:China (Mainland) Shandong

- HS Code:870892000

- Production Capacity:5000sets

Description

Pressure Boost

stainless steel vacuum cutout valve with normally open style

Our exhaust valve use the unique adjustment sleeve design, the regulating sleeve can be adjusted to suit for the different displacement cars, so it could meet different customer de mand.Here is our video for the adjustment sleeve design.

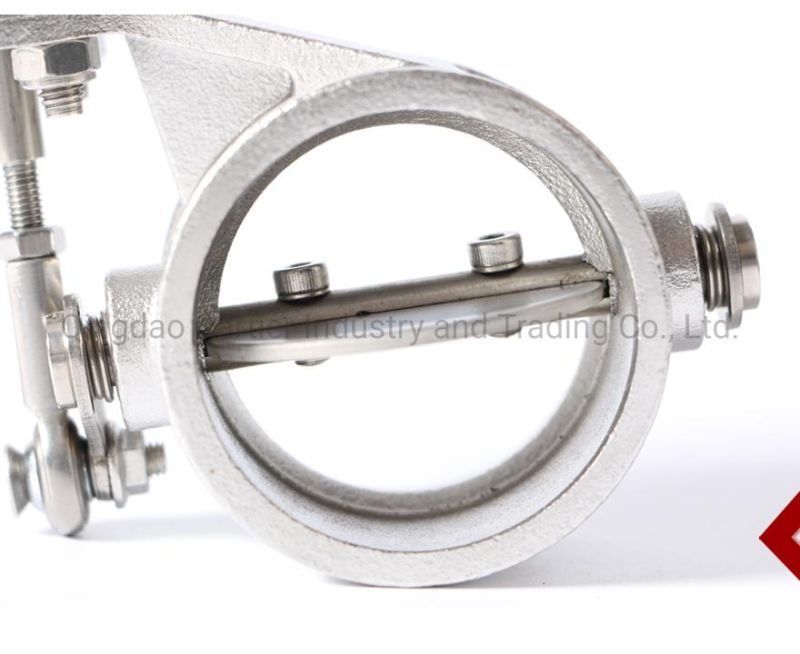

Specific titanium alloy precision casting body,silica sol process,with high precision, surface beauty.could hlep to improve the grade of products, easy to sell, can give customers a good visual experience, promote sale for you.This is our details pic tures, have a look pls.

Our exhaust valve use the four axis gang punching process (computer numerical control processing).the disc will not stuck,will let you enjoy its stable performance,and have high experience with it. Here is our other coustomer feedback after they install it.

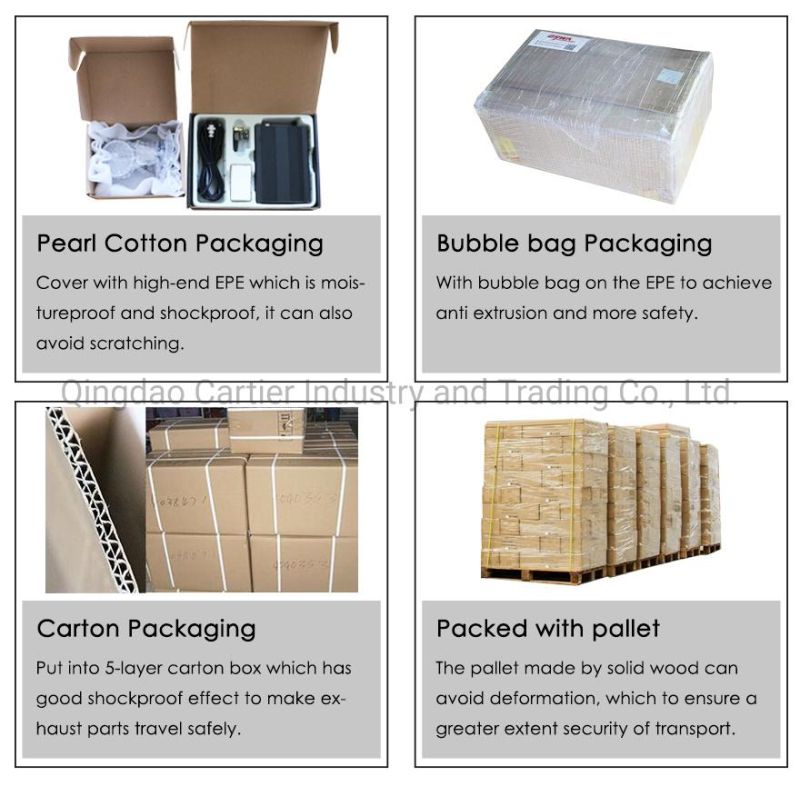

We use three-layer packaging. Wrap the anti-oxidation film firstly to prevent product from being oxidized and maintain the luster of the product.Then wrap the pearl cotton and bubble bag to protect the product from damage during trans portation,which can save repackaging cost, improve custom er satisfaction and recognition. Our three-way catalysts can be tested by loading, quality assurance, reduced repair rate, and increased customer satisfaction.

Elegant exhaust muffler valve by GRWA will help you make a style statement. Each product is manufactured from stainless steel for corrosion resistance and long service life and is polished for a highly reflective shine.Universal design fit on most cars.No matter what you need, please try to contact with us and we can satisfy you in the product style and quality. Stainless Steel Vacuum Cutout exhaust Valve with Normally Open Style The purpose of the transformation of the exhaust pipe is to adjust the level of exhaust back pressure, that is, the internal resistance of the exhaust pipe. The resistance size and the design angle of the head section, the thickness/catalyst size of the mid-tail section, the overall length and bending angle, and the loop of the tail muffler are all quite relevant. The main direction of retrofitting exhaust pipes in the past was to reduce the back pressure and make the intake and exhaust efficiency smoother. This changed the dynamic characteristics of the engine, adjusted the torque output timing, and enhanced the response and fluency of high-speed rotation. However, it hides the disadvantages that are unknown, that is, the loss of low-speed torque. The variable back pressure exhaust valve can be divided into two types, normally open and normally closed. The former is more suitable for street cars, while the latter is more suitable for semi-plant cars that will play in the next race.

Taking into account the horsepower and torque from the pipeline type change.From the perspective of the exhaust pipe reform theory above, it seems that it is quite complicated and difficult to create an exhaust pipe that takes into account horsepower and torque. It is even difficult to achieve. After all, you want to reduce exhaust emissions. Obstacles, but also want to maintain torque output, originally contrary to the argument, but such restrictions, in recent years, the introduction of "Variable Back Pressure Exhaust Valve", the ideal exhaust modification effect, it seems not far away!

The function of the device is just like its name. It is mainly used to control the size of the back pressure in the exhaust pipe. From the perspective of appearance, the overall mechanism design is like a throttle valve with a simple structure. A butterfly valve can be seen on the device. With vacuum actuator. Through the suction of the engine vacuum, the valve can be opened and closed. As long as the valve is installed in an appropriate position in the exhaust pipe system, the engine can have a balanced torque and horsepower performance. The principle of this system is to set a variable valve in the exhaust pipe. When the rotation speed is low, the valve will close so that the exhaust gas can be discharged from a smaller pipe diameter or a single pipe, and the back pressure in the exhaust pipe can be kept low. The torque is not lost; the valve will open at high speed, and the exhaust gas will be directly discharged through the large diameter position or double pipeline, so that the exhaust gas has more channels and outlet vent, and then reduce the back pressure in the exhaust pipe. As a result,

the continuity of the horsepower will have a more ideal performance.