Automotive Exhaust Systems, Ss Braided Exhaust Flex Pipe Manufacturers^

Comflex Industrial Co., Ltd.- Type:Exhaust Pipe

- Body Material:Steel

- Discharge Standard:Euro IV

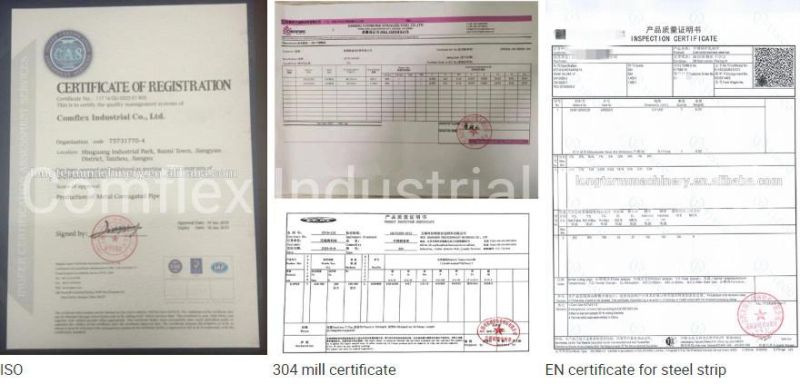

- Certification:ISO9001, CE

- Noise Source:The Noise of Engine

- The Noise of Engine:Mechanical Noise

Base Info

- Model NO.:Comflex

- Automobile Chassis Noise:Tire Noise

- Component:Exhaust Pipe

- Main Market:Universal

- Product Name:Ss Braided Exhaust Flex Pipe Manufacturers

- Size:Customized

- Material Grade:SS304,201,Carbon Steel

- Structure:Bellows+Outer Braid+Inner Braid,Interlock+Caps+Nip

- Productivity:100PCS,Hour

- Hose Type:Interlock,Double Lock

- Features:Extension-Type

- Length:100~400mm

- Thickness:1~12mm

- Bellow:Single Layer or Multi-Layer

- Transport Package:Standard Seaworthy Packing

- Specification:ID25~150mm

- Trademark:Comflex

- Origin:Wuxi

- HS Code:870892000

- Production Capacity:100sets,Months

Description

Basic Info.

Model NO. Comflex Automobile Chassis Noise Tire Noise Component Exhaust Pipe Main Market Universal Product Name Ss Braided Exhaust Flex Pipe Manufacturers Size Customized Material Grade SS304,201,Carbon Steel Structure Bellows+Outer Braid+Inner Braid/Interlock+Caps+Nip Productivity 100PCS/Hour Hose Type Interlock/Double Lock Features Extension-Type Length 100~400mm Thickness 1~12mm Bellow Single Layer or Multi-Layer Transport Package Standard Seaworthy Packing Specification ID25~150mm Trademark Comflex Origin Wuxi HS Code 870892000 Production Capacity 100sets/MonthsProduct Description

Automotive Exhaust Systems, SS Braided Exhaust Flex Pipe Manufacturers^Application:

Flexible Exhaust Pipe Connector:

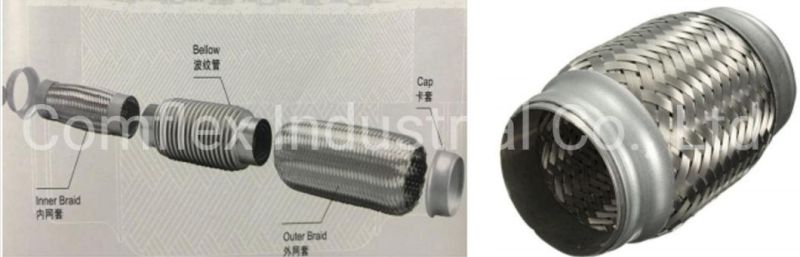

It is installed in the exhaust pipe between the engine exhaust branch pipe and the muffler, which makes the connection of the entire exhaust system flexible and plays a role in reducing noise. Easy to install and extend the life of exhaust noise reduction system.Mainly used for light trucks, small passenger cars and buses. The structure is a double-layer corrugated pipe covered with a steel wire mesh sleeve, and the two ends are a straight edge segment outer snap ring structure. In order to improve the noise reduction effect, an expansion joint or mesh sleeve can be installed in the bellows.

Product Details:

Double Layer Auto Exhaust Flexible Engine Pipe for truck

-1. Suitable for a wide range of the tail pipe link.-2. We can make parts with a high degree of flexibility.

-3. In particular, we increase the height of the bellows to enhance the effectiveness of vibration absorption.

-4. This product is used in exhaust system and high-and low-temperature.

-5. It can decrease engine noise and vibration.

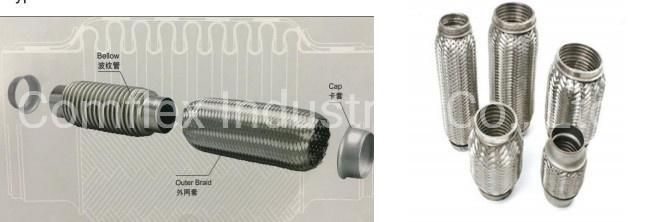

Type 1.

Interlock Pipe + Bellow + Outer Braid + Cap

Type 2.

Bellow + Outer Braid + Cap

Type 3.

Interlock Pipe + Bellow + Outer Braid + Cap

Auto Exhaust Bellow Production Line:

1. Automobile exhaust flexible pipe forming machine

A. Automatic vertical bellow forming machine(One stroke one piece)

* Size range: 32-100mm

* Thickness range: 0.3mm-1mm

* Working principle: Hydraulic

B. YKCX-65D automatic bellow forming machine

* Inner diameter of the bellow: 16-60mm

* Thickness of the bellow: customized acceptable

* Toolings/different size changing time is about 15 minutes

* Capacity: 10 seconds for one convolution

* Length of tube before forming: L≤1000mm.

* Use feeding cylinder

2. Automobile exhaust bellow assembly machine

A. Bellow compressing machine B. Cap crimping machine

C. Bellow end trimming machine(single head or double head)

D. Interlock hose making machine E. Wire braiding machine

Certifications:

Package&Delivery:

Company Profile:

We are a professional manufacturer of all types of metal flexible metal hose making machines and machinery with more than 35 years of history, such as corrugated metal hose making machine, interlock hose making machine etc... These hoses are widely used in energy, petroleum, petrochemical, machinery, refrigeration, construction, hydropower, nuclear power, cement, paper, medicine, transportation, mining, metallurgy, urban central heating, shipbuilding, city gas, natural gas pipeline construction, Central air conditioning, aerospace and other industries. Our machines have exported to many countries such as Russia, Ukraine, USA, Australia, New Zealand, Poland, etc..

FAQ

Q: Why so many suppliers choose us?

A: Because we are one of the most professional manufacturers of the flexible exhaust pipe with more than 25 years of experience.

Q: What is the delivery time about the order?

A: The delivery time would be depended to your quantity, usually from 7~20 days

Q: How about the payment terms?

A: Normally 30% deposit in advance, the balance should paid before shipment.

Q: Do you provide samples? Is it free or charged?

A: Yes, we can offer free samples but courier costs covered by the customer.

Q: Can the products be manufactuered by customer's requirement?

A: Yes, the specifications stated above are the standard ones, we can design and manufacture as requirement.